Nitriding

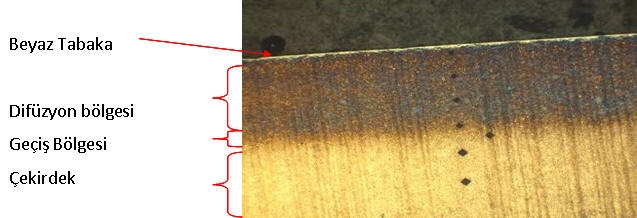

Nitriding, a low temperature surface hardening process, is based on implementing nitrogen atoms on the steel piece surface as interstitial pace atoms and creating a hard layer on the surface. In general nitriding temperature for all steel types is between 480-590°C. Because fast cooling speed is not necessary and low application temperatures are suitable for the process, the level of distortion on the pieces is minimum.

Some advantages of nitriding process are as follows:

* Increase in wear resistance

* Increase in corrosion resistance

* High surface hardness